Our concept for top performance:

comprehensive know-how!

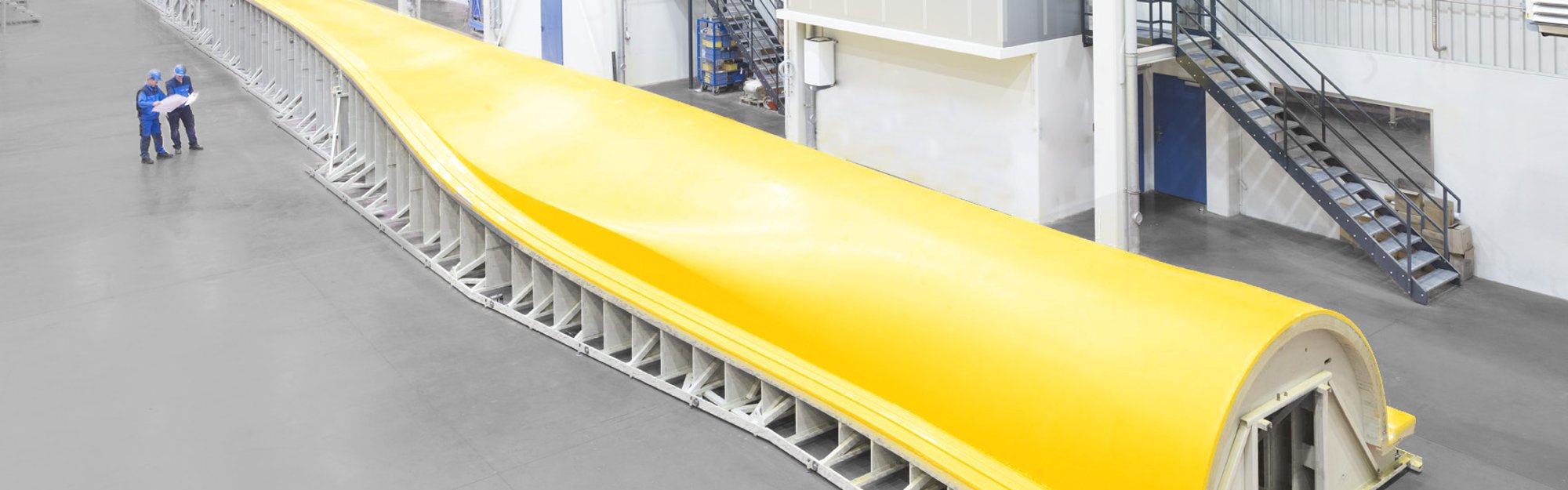

The foundation for the innovative drive and success across all of SCHÜTZ’s business units is our company’s technological competence – paired with the ambition to stay independent from suppliers by ensuring that our manufacturing depth is as great as possible. This allows us to guarantee uniform quality standards all over the world and gives our customers the peace of mind of knowing that they can depend on the same high SCHÜTZ quality anywhere in the world.